Website

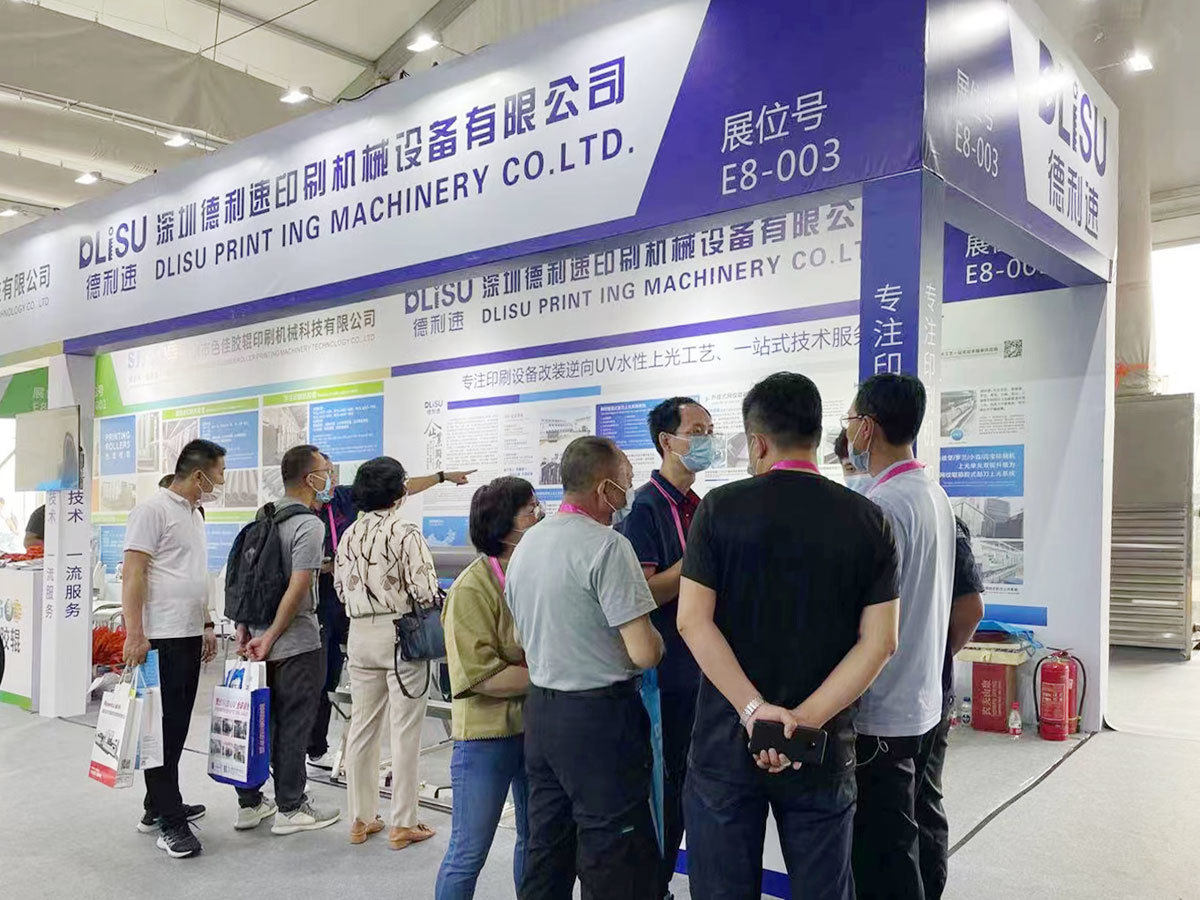

Shenzhen Dlisu Printing Machinery Co., Ltd.

Shenzhen Address: 803, Shenbao Building, No. 219, Zhenming Road, Gongming Street, Guangming New District, Shenzhen

Shantou Address: Wanji Industrial Zone (Second Branch Road), Longhu District, Shantou City

Tel: 86-754-87224116

Phone: 86-137-5047-4043

86-138-2327-5809 86-159-1664-0313

Fax: 86-754-87224116

QQ: 815887412

E-Mail:dlisu888@163.com